100% Made in Italy Chucks Production

Production of

Chucks and Special Chicks

Italian quality

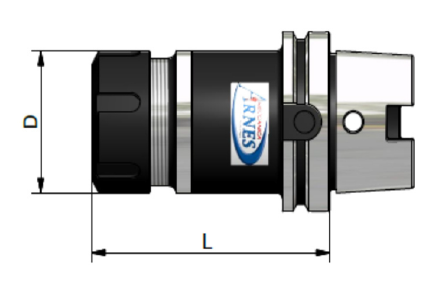

Meccanica Arnes designs and manufactures various kinds of chucks, that can be installed on any type of machine tool.

Our mechanical workshop, which has been active for many years and has now become a point of reference in the sector, carries out standard and custom-made projects to meet the demands of all customers, even the most demanding ones.

All our products, 100 % Made in Italy, are crafted from high-quality materials in order to respect the standards of Italian excellence. Do not hesitate to contact us to request more information, or to request a free no-obligation quote: call us, send us a message via email or via the form you will find in the contact section. We design and manufacture spindles that can be installed on any type of machine tool on which a chuck can be mounted, which allows you to clamp and hold any piece being machined as well as to drag a tool or piece in rotation, whether it is a drill bit. or milling, an axial symmetrical piece or of other generic shapes, in order to be able to perform a certain type of machining on / with it.

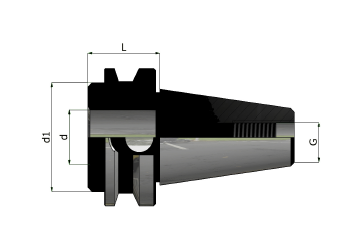

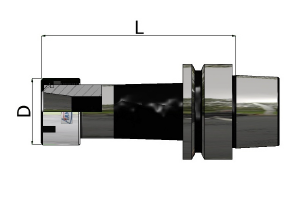

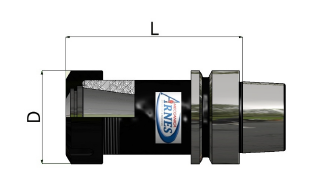

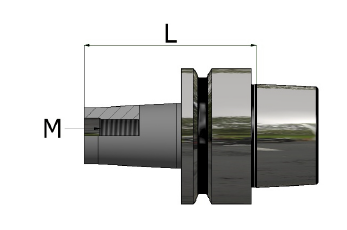

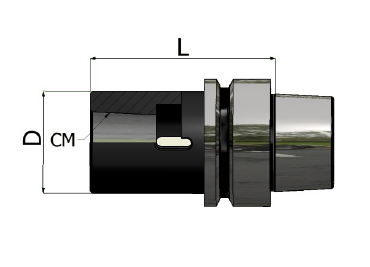

High speed chucks

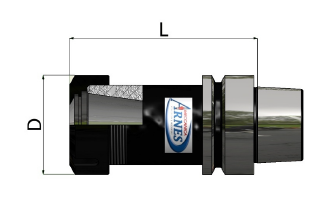

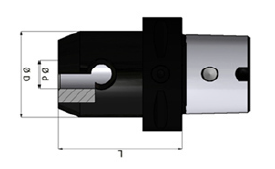

ISO 10 Chucks

City skyline

Features and Benefits:

- High speed collet chucks;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

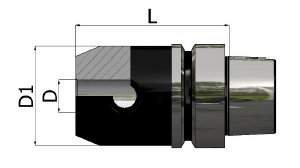

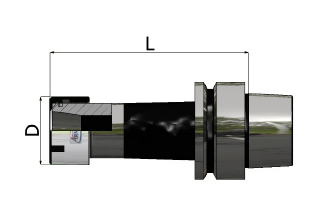

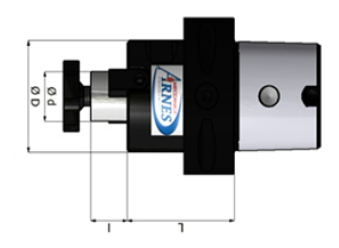

ISO 15 Chucks

City skyline

Features and Benefits:

- High speed collet chucks;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

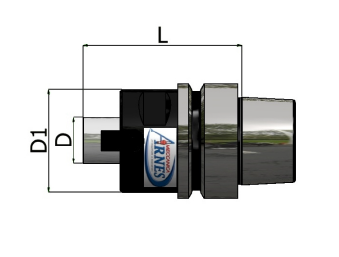

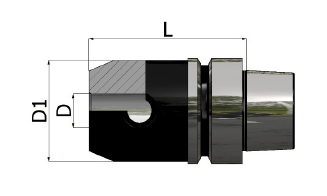

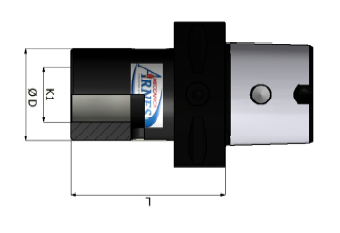

ISO 20 Chucks

City skyline

Features and Benefits:

- High speed collet chuck;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

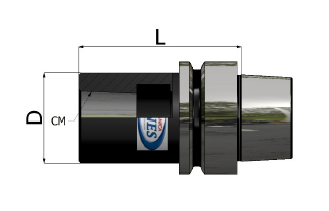

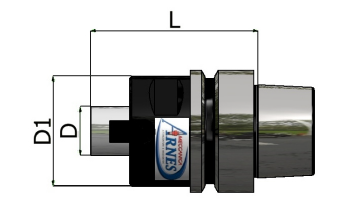

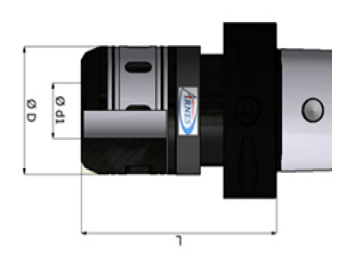

ISO 25 Chucks

City skyline

Features and Benefits:

- High speed collet chuck;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

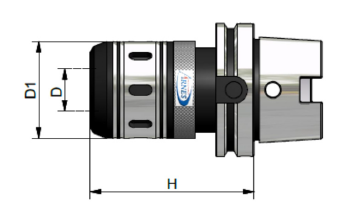

HSK 25 E Chucks

City skyline

Features and Benefits:

- High speed collet chuck;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

HSK 32 E Chucks

City skyline

Features and Benefits:

- High speed collet chuck;

- Customized according to customer needs.

Usage:

suitable for machining centers with / without electrospindle.

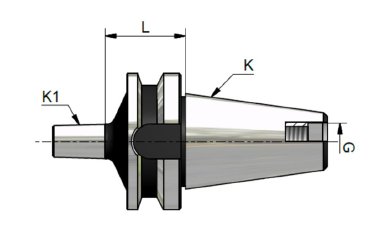

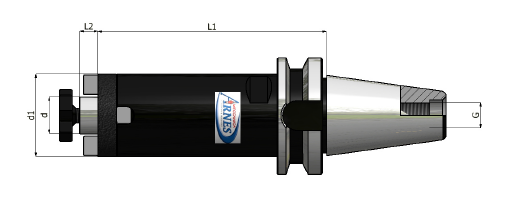

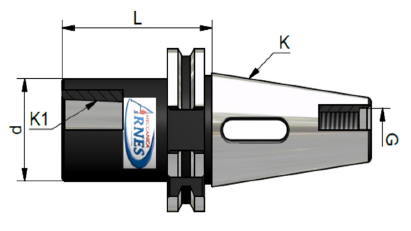

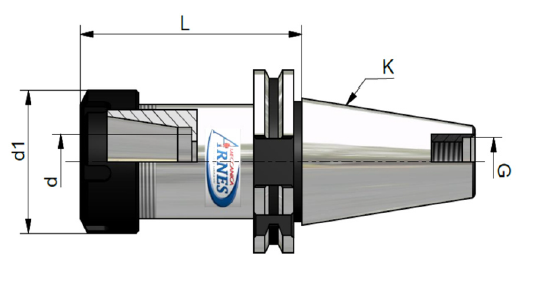

MAS 403 BT Chucks

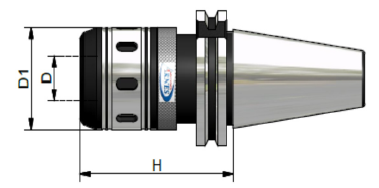

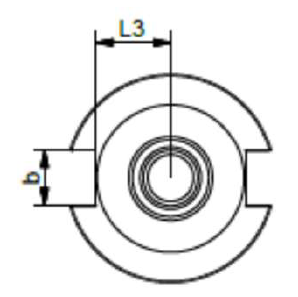

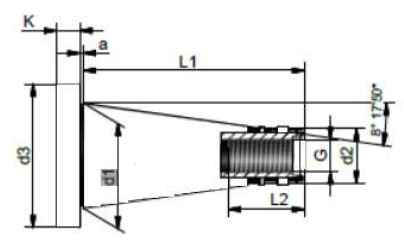

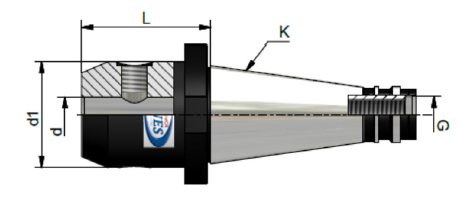

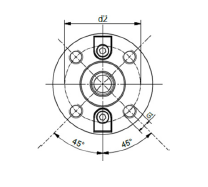

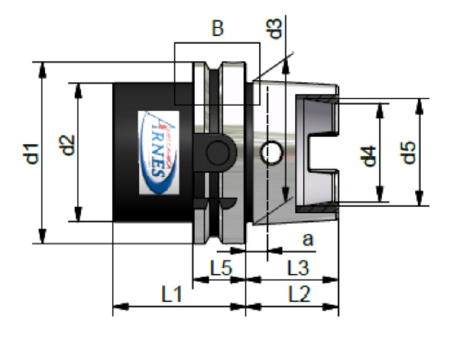

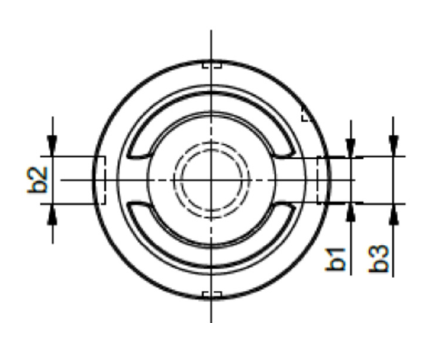

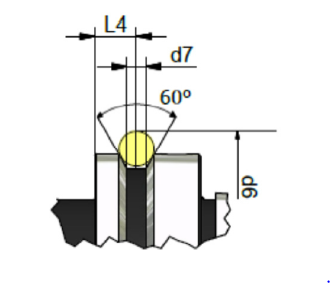

MAS-BT403 Chucks Technical Features

Coolant through both spindle centre and flange

Standard Balancing:: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

City skyline

Birthday Sparks

Fashion Magazine

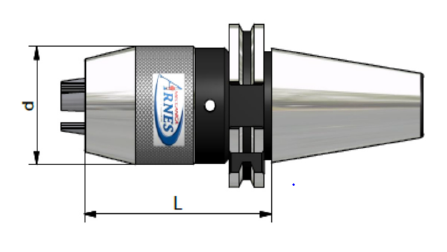

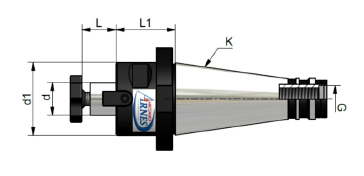

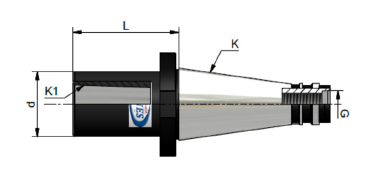

ER Standard Collet Chucks

City skyline

ISO 45 tapers on request

Standard balance: 12,000 RPM G: 6.3

On request: 20,000 / 30,000 RPM G: 2,5

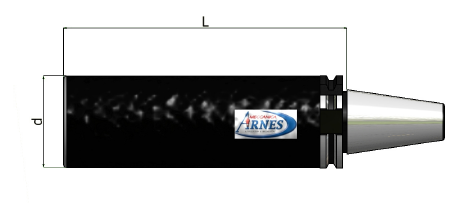

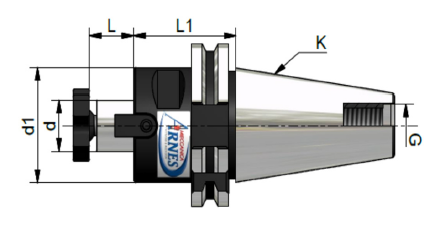

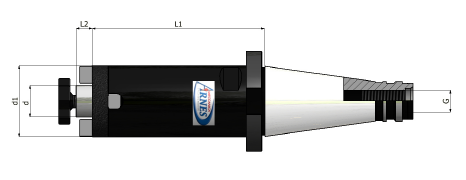

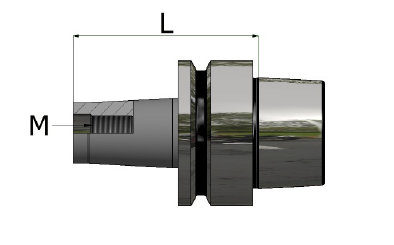

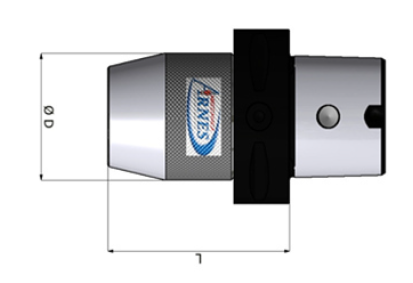

ER Mini Collet Chucks

City skyline

Standard balance: 12,000 RPM G: 6.3

On request: 20,000 / 30,000 RPM G: 2,5

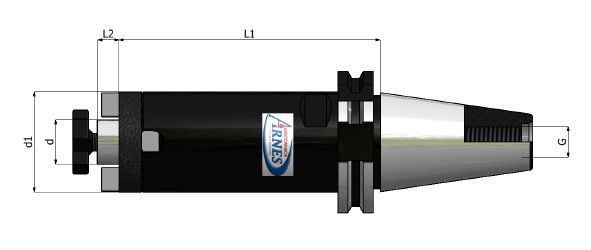

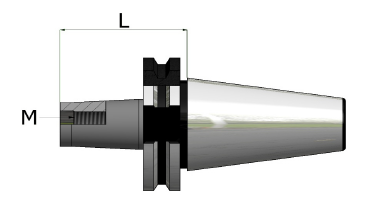

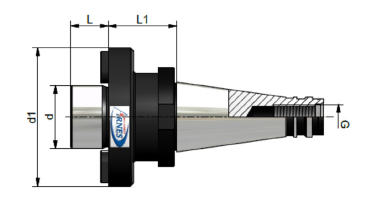

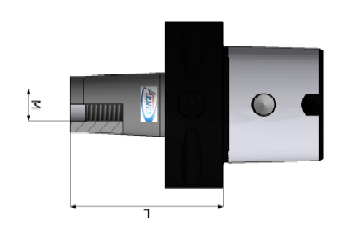

Weldon Extra short

Standard balance: 12,000 RPM G: 6.3

On request: 20,000 / 30,000 RPM G: 2,5

City skyline

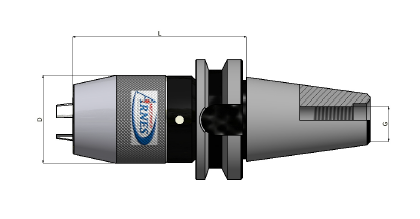

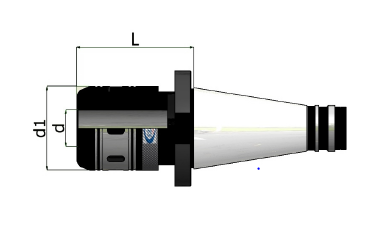

Integral Drill Chucks Form A

City skyline

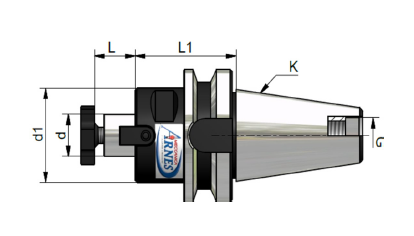

End mill chucks with fixed dragging Form A D

City skyline

Combined end mill chucks

Form A D

City skyline

End mill chucks for cutters

with inserts

City skyline

Birthday Sparks

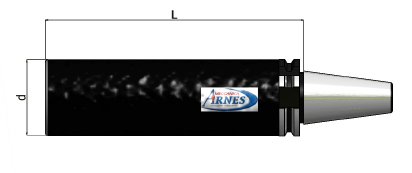

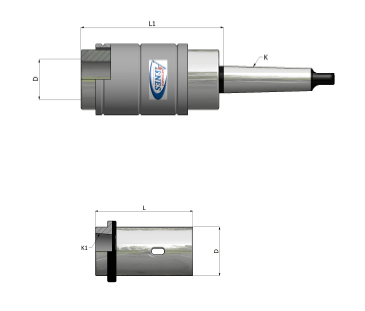

Morse taper reducer sleeve for cutters

City skyline

Morse taper reducer sleeve for drills holders Form A D

City skyline

ISO 45 tapers on request

ISO taper reducer sleeve

City skyline

High clamping chucks

City skyline

Standard Balancing:12.000 RPM G: 6,3

On request 20.000/30.000 RPM G:2,5

Threaded connection chucks

City skyline

Standard Balancing: 20.000 RPM G: 2,5

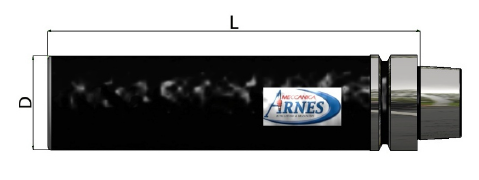

Rotary coolant feeder

City skyline

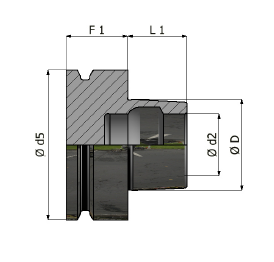

Tool holder blanks Form A

City skyline

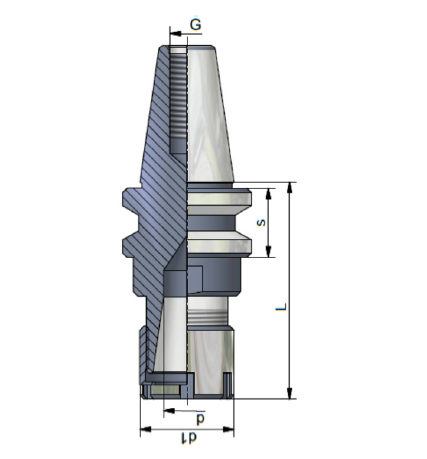

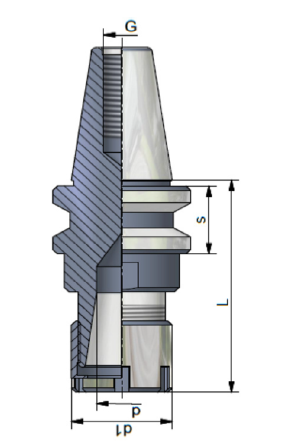

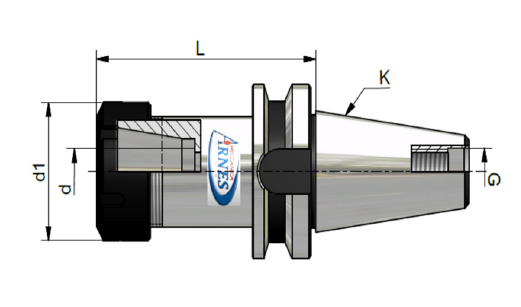

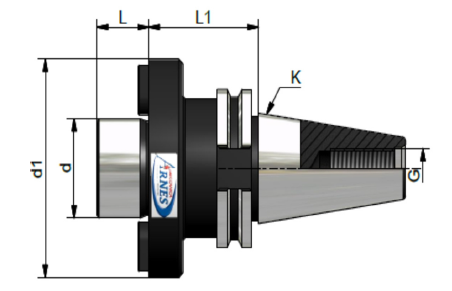

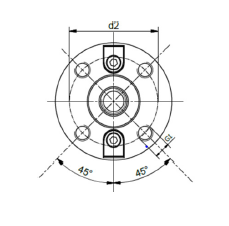

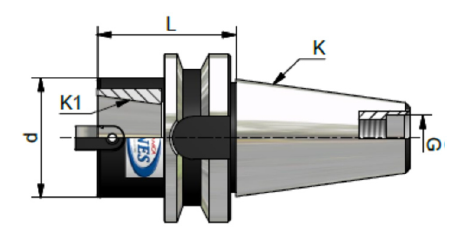

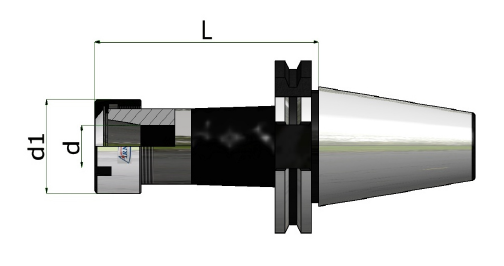

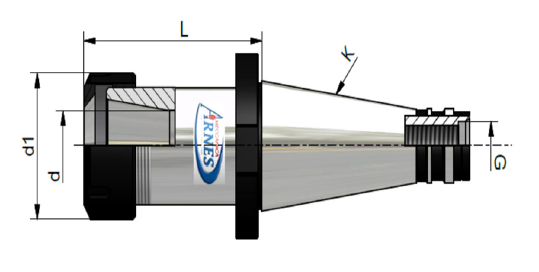

DIN 69871 Form AD+B ISO 7388/1 Chucks

Chucks DIN 69871 Form AD+B ISO 7388/1

City skyline

Birthday Sparks

Fashion Magazine

Water inlet from both the center of the chuck and from the flange

Standard balance: 12,000 RPM G: 6.3

On request: 20,000 / 30,000 RPM G: 2,5

Collet chucks ER Standard

City skyline

Standard Balance: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

ISO 45 tapers on request

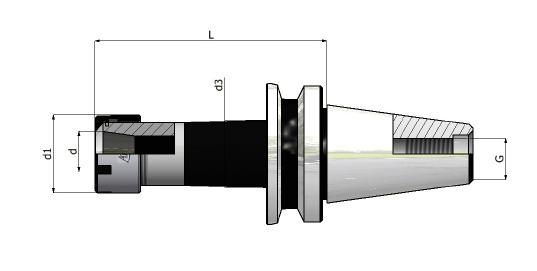

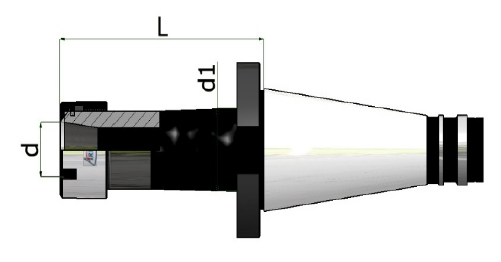

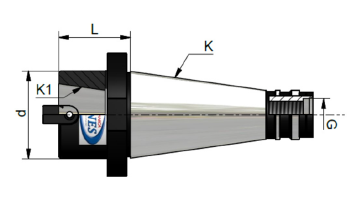

Collet chucks ER Mini

City skyline

Standard Balance: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

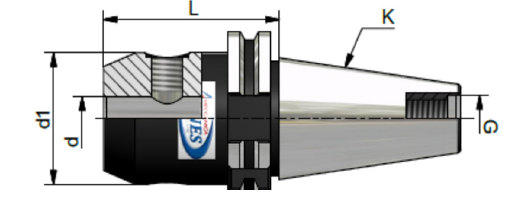

Weldon

City skyline

Standard Balance: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

ISO 45 tapers on request

Weldon Extra short

City skyline

Standard balance: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

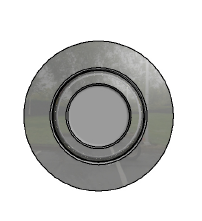

Integral drill chucks

City skyline

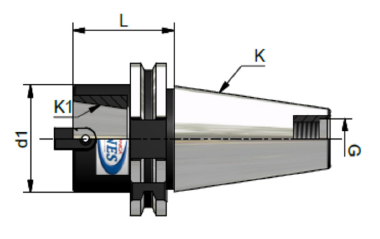

End mill chucks with fixed dragging

City skyline

Combined end mill chucks

City skyline

End mill chucks for cutters with inserts

City skyline

Birthday Sparks

Morse taper reducer sleeve for milling cutters Form AD

City skyline

ISO 45 tapers on request

Morse taper reducer sleeve for drills holders

City skyline

ISO 45 tapers on request

ISO taper reducer sleeve

Form A

City skyline

High clamping chucks

City skyline

Standard balance: 12.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

Threaded connection chucks

City skyline

Standard balance: 20.000 RPM G: 2,5

Rotary coolant feeder

City skyline

Standard balance: 20.000 RPM G: 2,5

Tool holder blanks Form A

City skyline

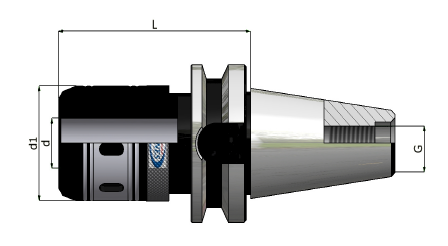

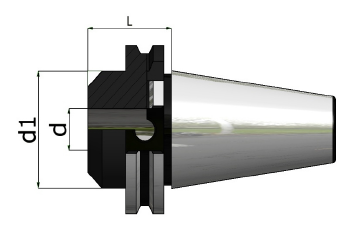

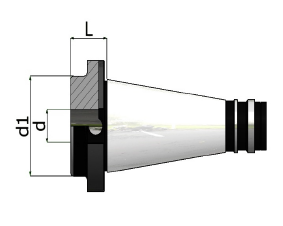

DIN 2080 Chucks

DIN 2080 Chucks

technical features

City skyline

Birthday Sparks

Fashion Magazine

Collet Chucks ER Mini

City skyline

Weldon

City skyline

Weldon extra short

City skyline

Integral drill chucks

City skyline

End mill chucks with fixed dragging

City skyline

Combined end mill chucks

City skyline

End mill chucks for cutters with inserts

City skyline

Birthday Sparks

Morse taper reducer sleeve for drills holders

City skyline

ISO 45 tapers on request

Morse taper reducer sleeve for drills holders

City skyline

ISO 45 tapers on request

High clamping chucks

City skyline

Tool holder blanks

City skyline

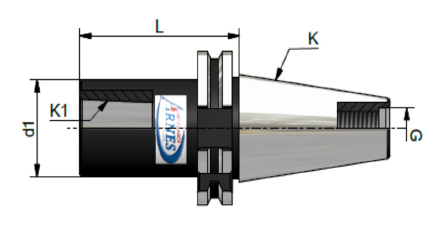

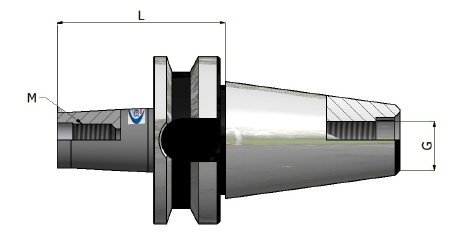

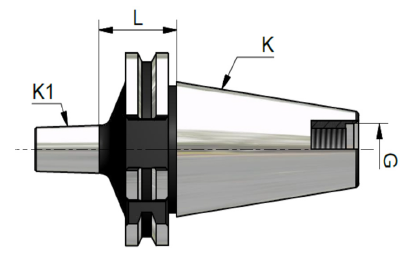

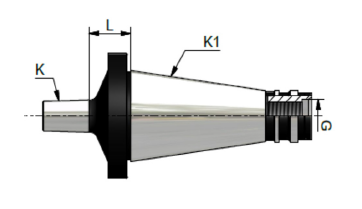

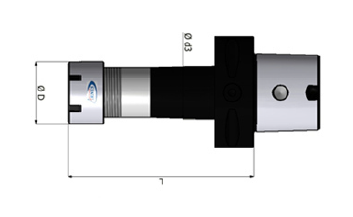

HSK Chucks

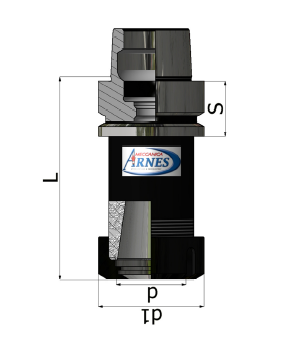

Chucks HSK Form A - E - F

technical features

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

City skyline

Birthday Sparks

Fashion Magazine

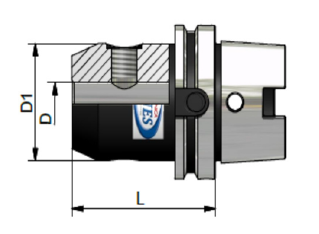

Collet chucks ER Standard

Form A

City skyline

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

Collet chucks ER Mini Form A

City skyline

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

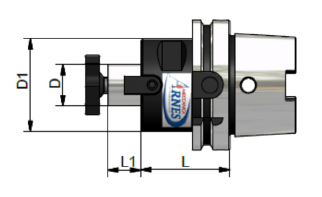

Weldon Form A

City skyline

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

End mill chucks with fixed dragging Form A

City skyline

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

Morse taper reducer sleeve for drills cutters Form A

City skyline

Morse taper reducer sleeve for drills cutters Form A

City skyline

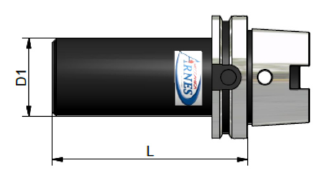

High clamping chucks Form A

City skyline

Standard Balance: 12.000 RPM G: 6,3

Threaded connection chucks Form A

City skyline

Standard balance: 25.000 RPM G: 2,5

Tool holder blanks Form A

City skyline

Standard Balance: 15.000 RPM G: 6,3

On request: 20.000 / 30.000 RPM G: 2,5

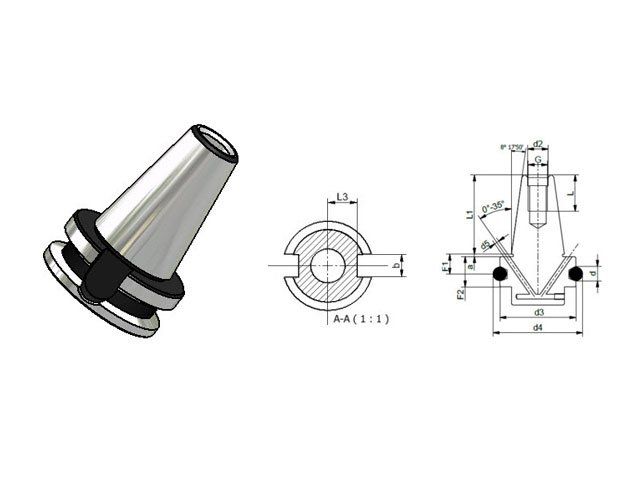

HSK Chucks Form E

technical features

Standard Balance: 20.000 RPM G: 2,5

City skyline

Collet chucks ER Standard

Form E

City skyline

Standard Balance: 20.000 RPM G: 2,5

Collet chucks ER Mini Form E

City skyline

Standard Balance: 20.000 RPM G: 2,5

End mill chucks with fixed dragging Form E

City skyline

Standard Balance: 20.000 RPM G: 2,5

Morse taper reducer sleeve for drills cutters Form E

City skyline

Threaded connection chucks Form E

City skyline

Standard Balance: 20.000 RPM G: 2,5

Threaded connection chucks Form E

City skyline

Tool holder blanks Form E

City skyline

HSK Chucks Form F

technical features

Standard Balance: 20.000 RPM G: 2,5

City skyline

Birthday Sparks

Collet chucks ER Standard

Form F

City skyline

Standard Balance: 20.000 RPM G: 2,5

Collet chucks ER Mini Form F

City skyline

Standard Balance: 20.000 RPM G: 2,5

End mill chucks with fixed dragging Form F

City skyline

Standard Balance: 20.000 RPM G: 2,5

Morse taper reducer sleeve for drill cutters Form F

City skyline

Morse taper reducer sleeve for drill cutters Form F

City skyline

Threaded connection chucks Form F

City skyline

Standard Balance: 20.000 RPM G: 2,5

Tool holder blanks Form F

City skyline

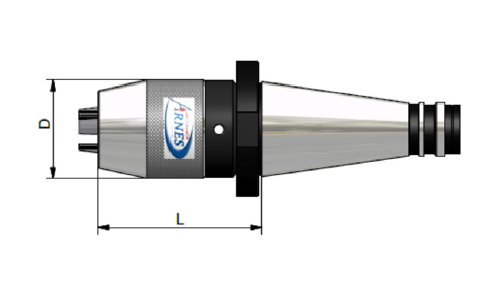

CAPTO ISO 26623-1 Chucks

Collet Chucks ER Standard

City skyline

Collet Chucks ER Mini

City skyline

Weldon

City skyline

End mill chucks with fixed dragging

City skyline

Morse taper reducer sleeve for drills holders

City skyline

High clamping chucks

City skyline

Threaded connection chucks

City skyline

Tool holder blanks

City skyline

Integral with spanner

City skyline

Quick-change tapping attachments

City skyline

MT and Cylindrical connection chucks

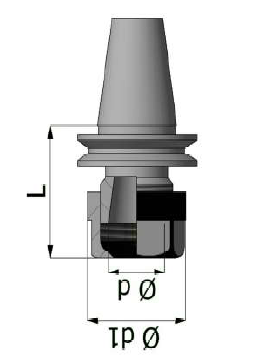

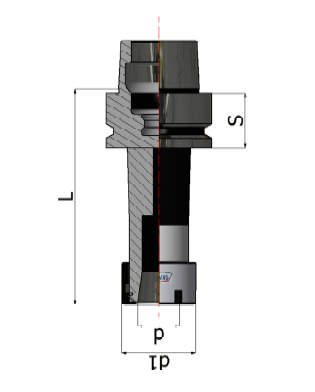

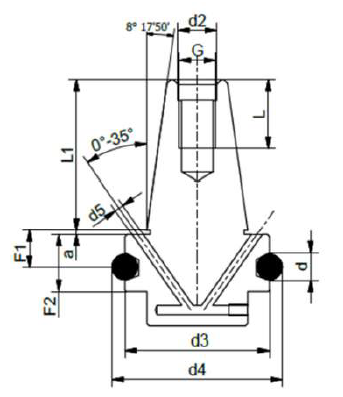

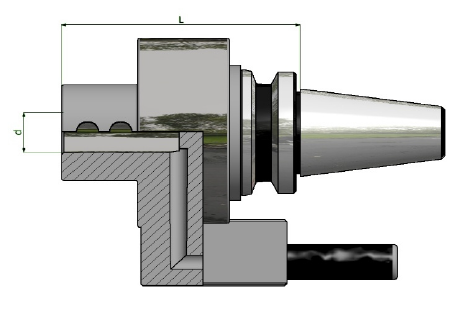

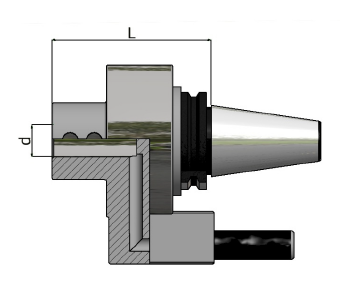

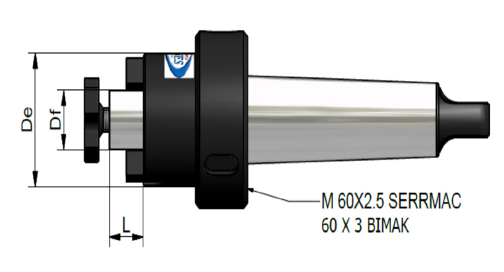

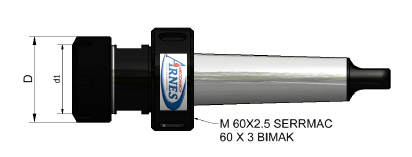

End mill chucks RAG –Bimak

Features and Advantages:

The ring nut of these chucks ensures an additional

clamping of the taper to the machine tool.

Usage: on drilling-milling machines.

Ring nuts with special threads for other drilling-milling machines on request.

City skyline

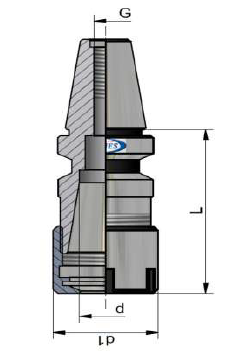

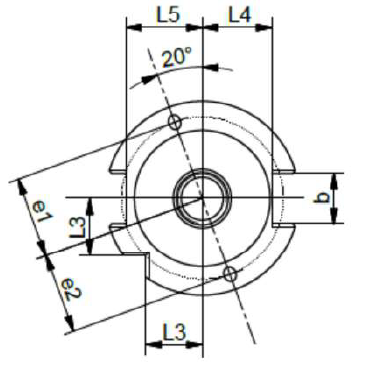

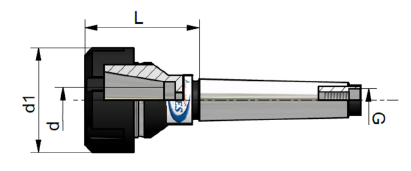

ER End mill chucks RAG –Bimak

Features and Advantages:

The clamping nut of these chucks ensures an additional clamping of the taper to the machine tool.

Usage: on drilling-milling machines.

Ring nuts with special threads for other drilling-milling machines on request.

City skyline

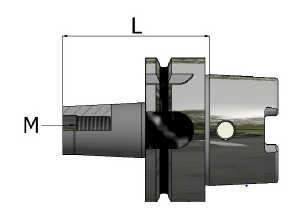

Collet chucks with morse taper connection

City skyline

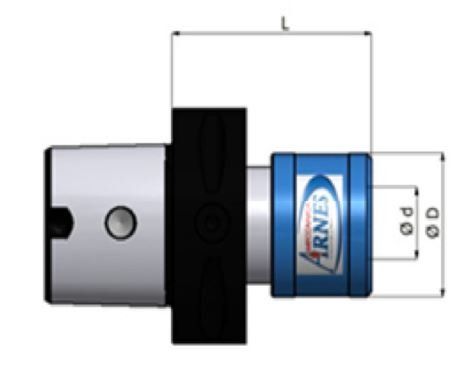

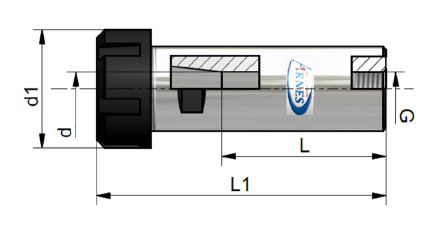

Collet chucks with cylindrical connection

Usage: on CNC machines.

City skyline

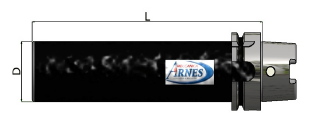

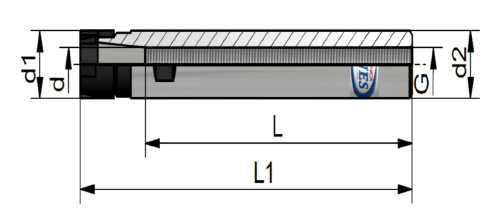

Collet chucks with extended cylindrical connection

Features and advantages:

Allows to work in deep narrow spaces with

limited working dimensions.

Usage: on CNC machines.

City skyline

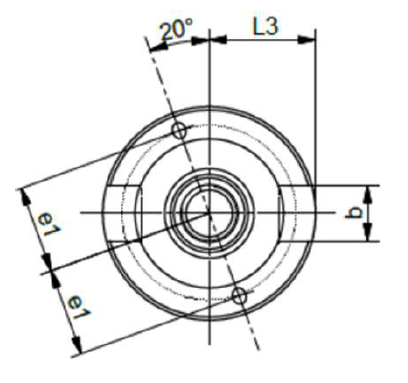

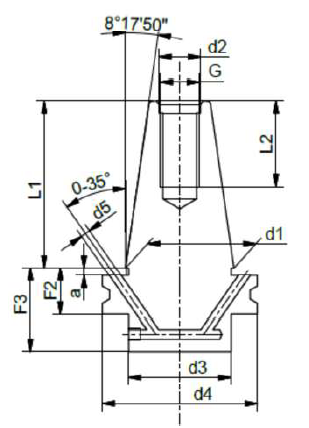

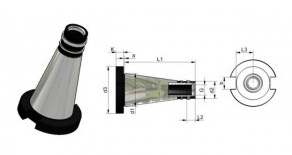

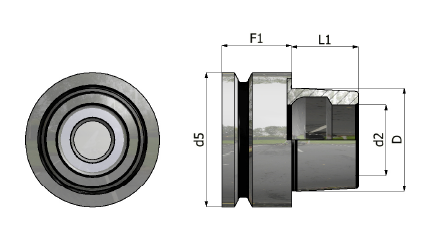

Quick-change morse taper connection and

bushing chuck

Features and advantages:

- Spindle and bushing chuck with morse taper connection suitable for medium and big sized drilling

- machine;

- Very quickly tool change

Usage: on column drills.